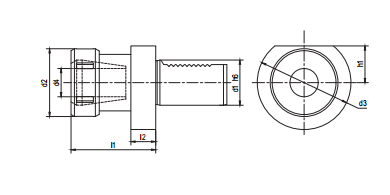

VDI OZ Collet Chuck Form E3

High Precision VDI OZ Collet Chuck Form E3 CNC lathe tool holder

VDI OZ Collet Chuck

Description

Product Description

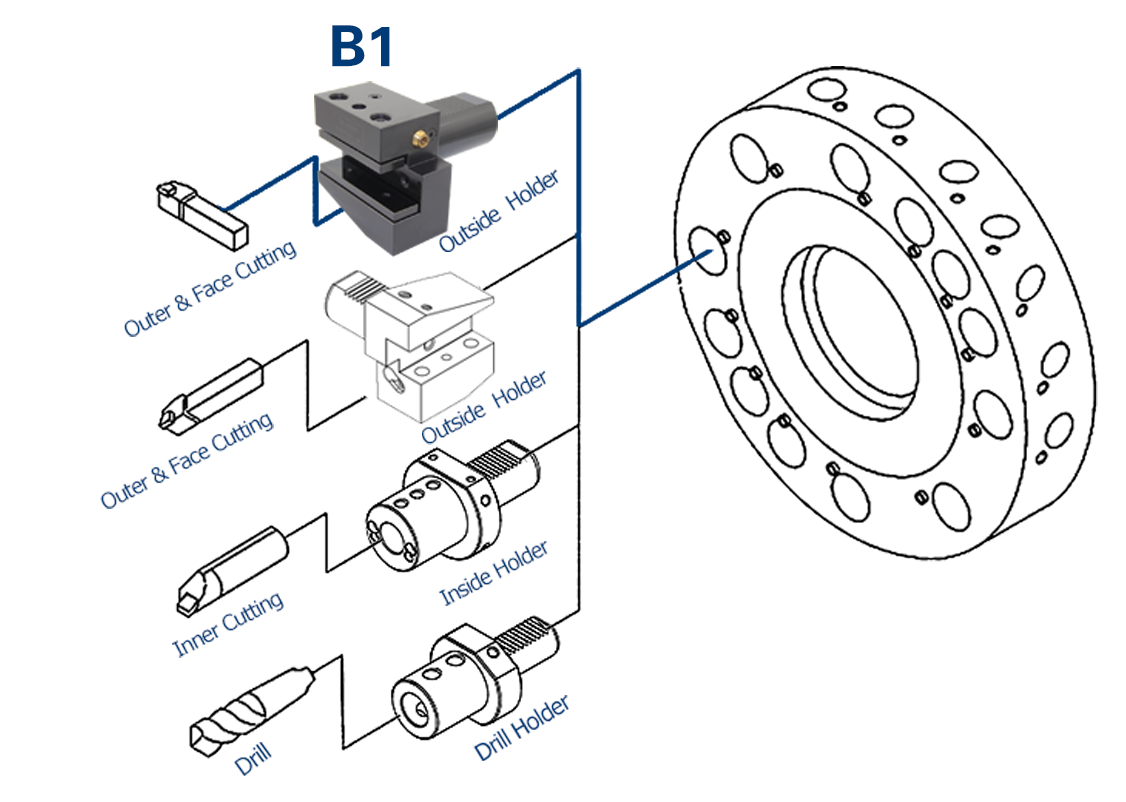

It is essential machine tool accessories for working center of CNC machine ,We produce according to German DIN69880 standard,It feature developed structure,high accuracy,convenient and alternative etc,It can satisfy the needs of turning,drilling,boring and milling etc,With variours tool holders and allocate different types tool and accessory,

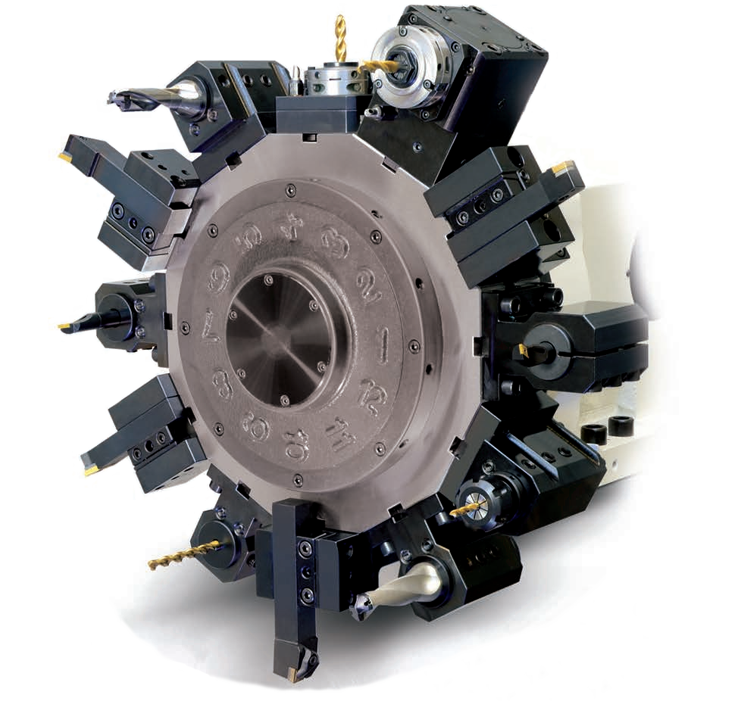

DIN69880 Standard VDI Toolholders

VDI is a Quick Change Toolholding System. VDI Provides a fast and accurate way of affixing tools to the Turret : Tool Changes are performed in seconds. Toolholders can be Preset. This is a Cam Operated Clamping System.

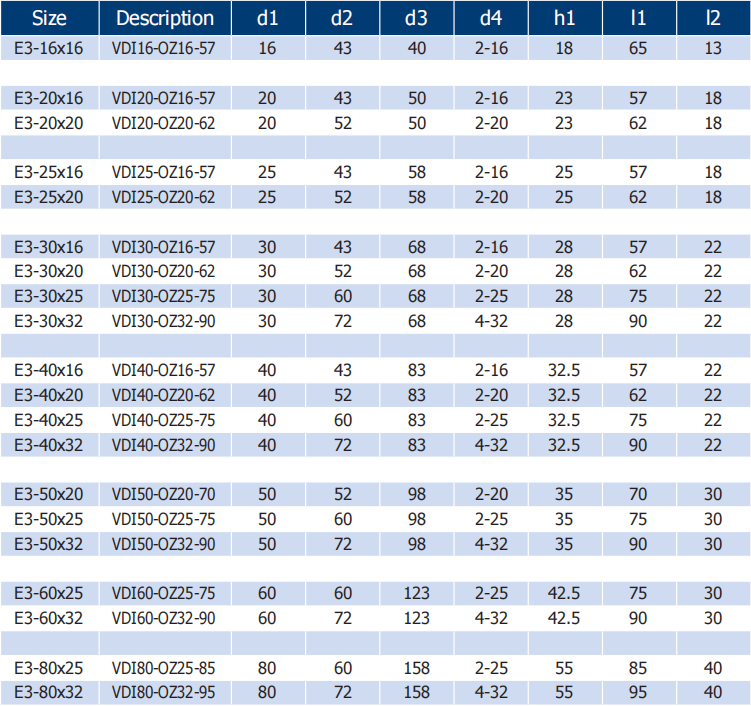

VDI tool holders are formed with reference to the DIN 69880, with the new unique technology. Such kind of VDI tool holder also has the capacity to stand by every side of the industrial improvement. Our quality tools are manufactured using hardened steel 20MnTi

All VDI Tool Holders are made to ISO 9001/2000 specifications.

Available in All Metric VDI Shank Sizes: 20mm,30mm, 40mm, 50mm, 60mm .

VDI Shank Type includes VDI20, VDI30, VDI40, VDI50

VDI can be used for Lathes, CNC Turning Lathes, Horizontal Lathes, Vertical Lathes, Turning machines, CNC Turning Centers