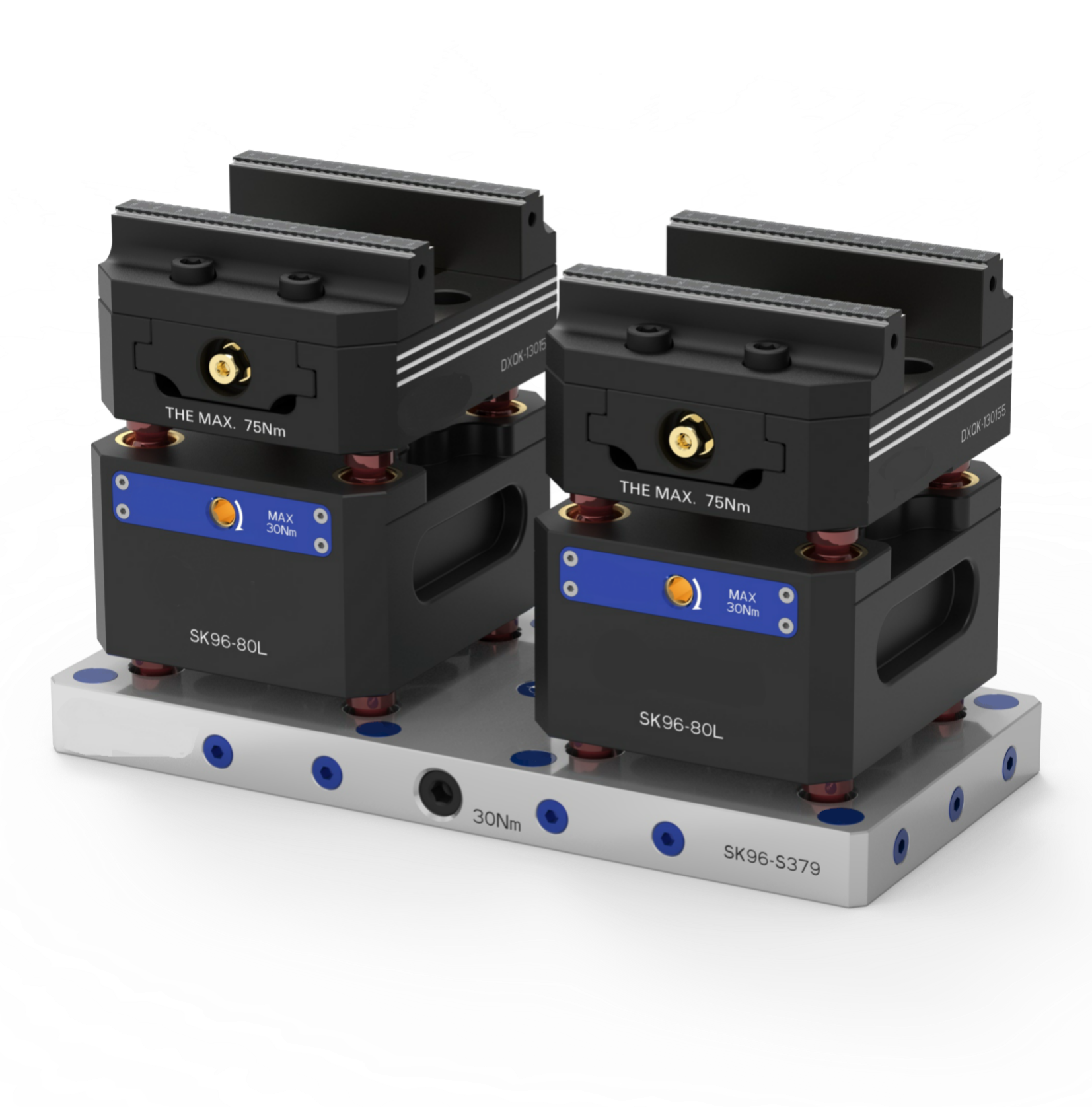

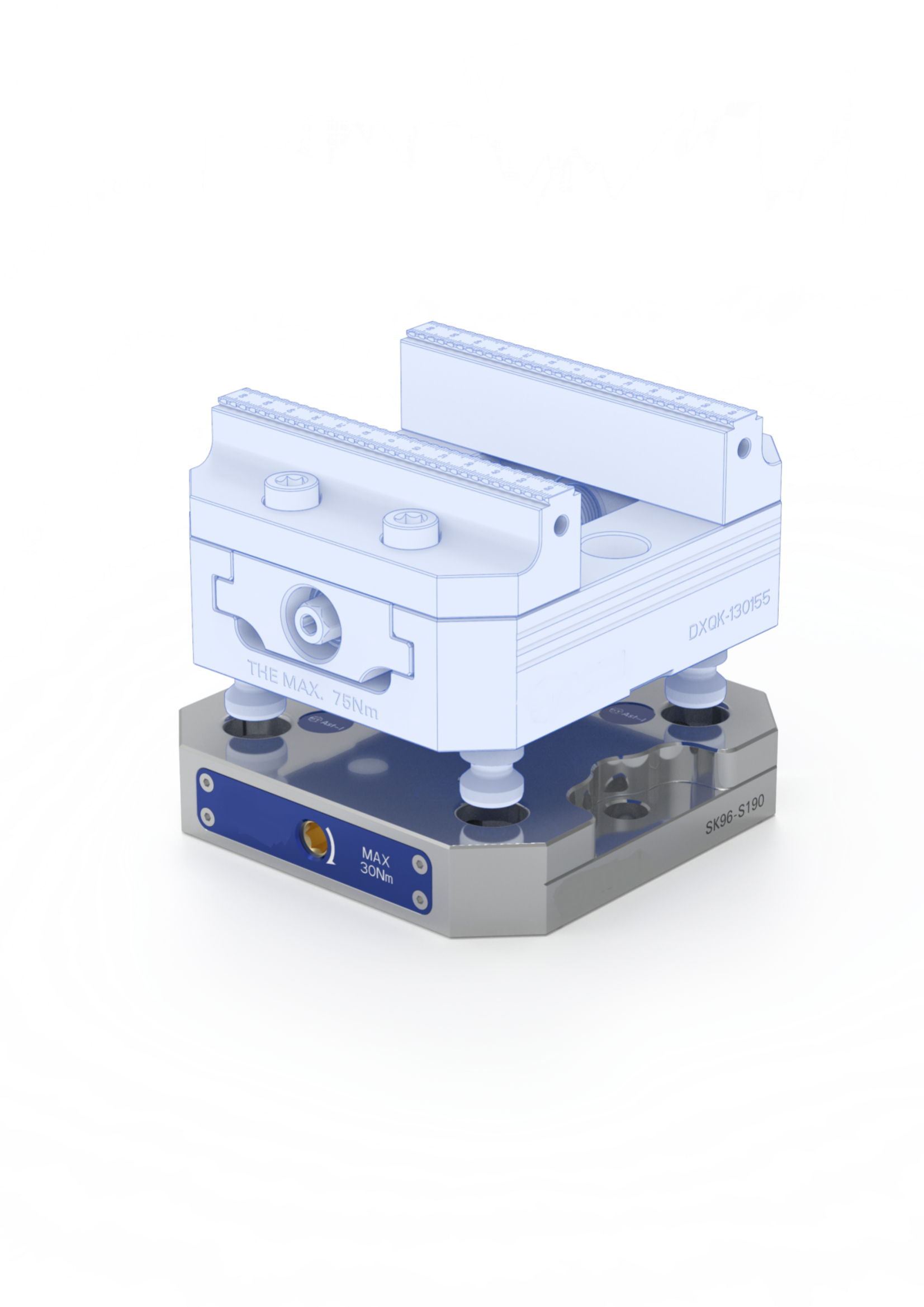

Modular quick-change clamping system

Each product and each new process requires a dedicated fixture and adapter tool plate. This is actually one of the biggest reasons affecting the efficiency of machine tools. A large amount of adaptation work makes it difficult for high-precision machine tools to fully exert their capabilities. We should pay attention to the direction of clamping technology, and the efficient combination of quick change + clamp is the top priority.

Description

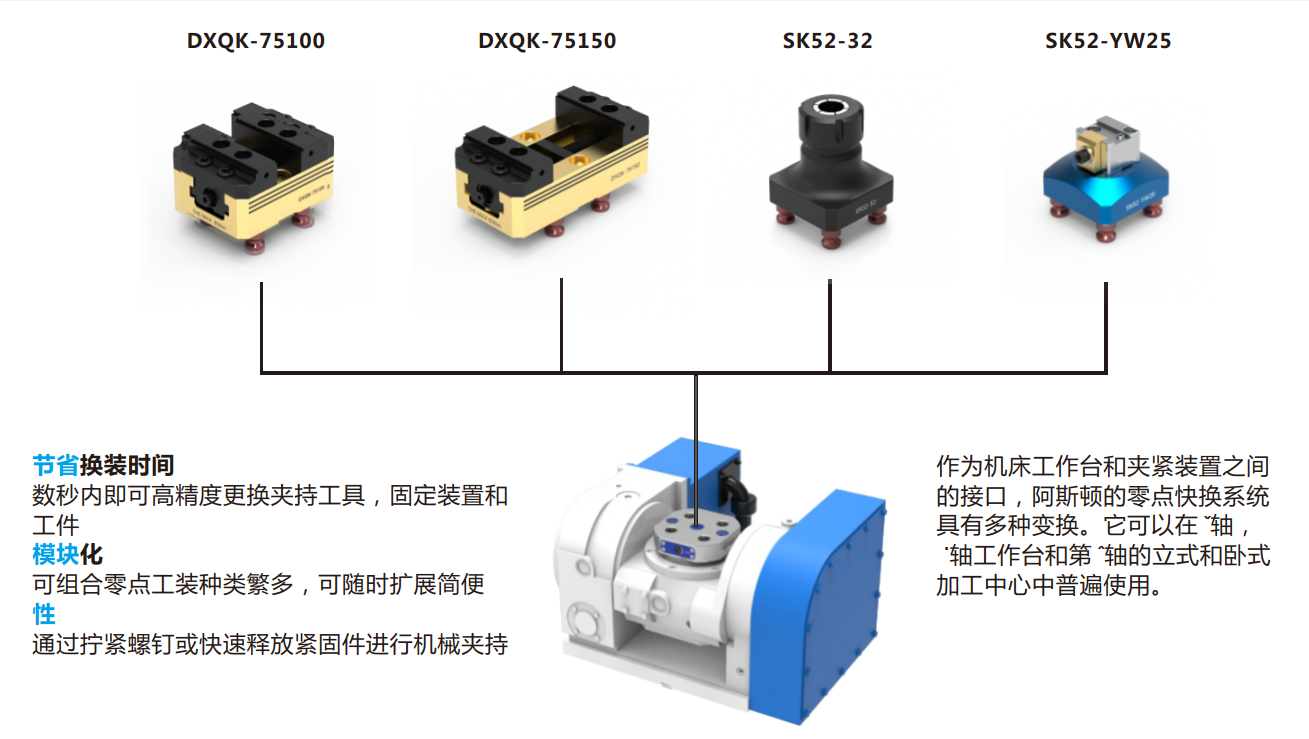

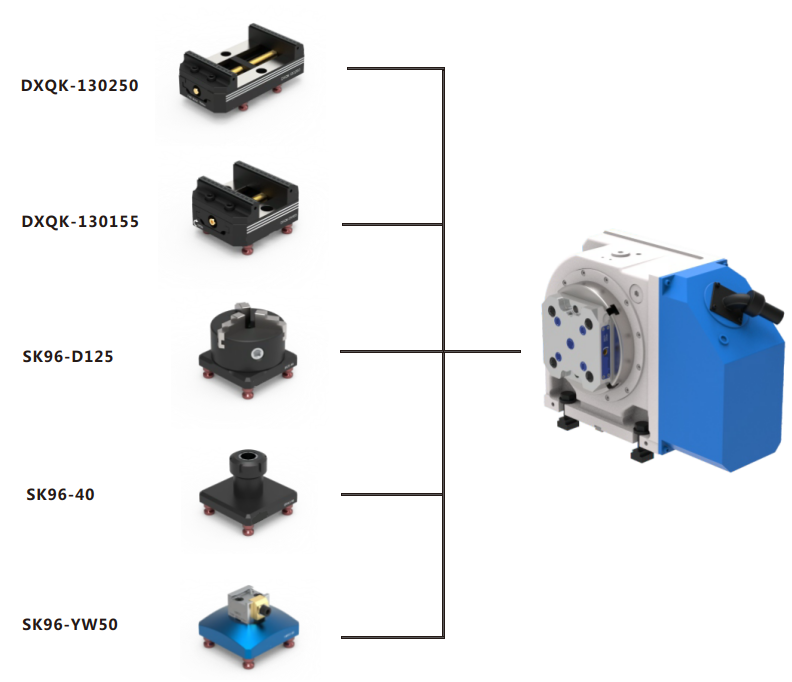

1. Save time when changing clothes

Clamping tools, fixtures and workpieces can be changed with high precision within seconds.

2.Modularization

There are many kinds of combinable zero-point tooling, which can be expanded at any time.

3. Simplicity

Mechanical clamping by tightening screws or quick release fasteners.

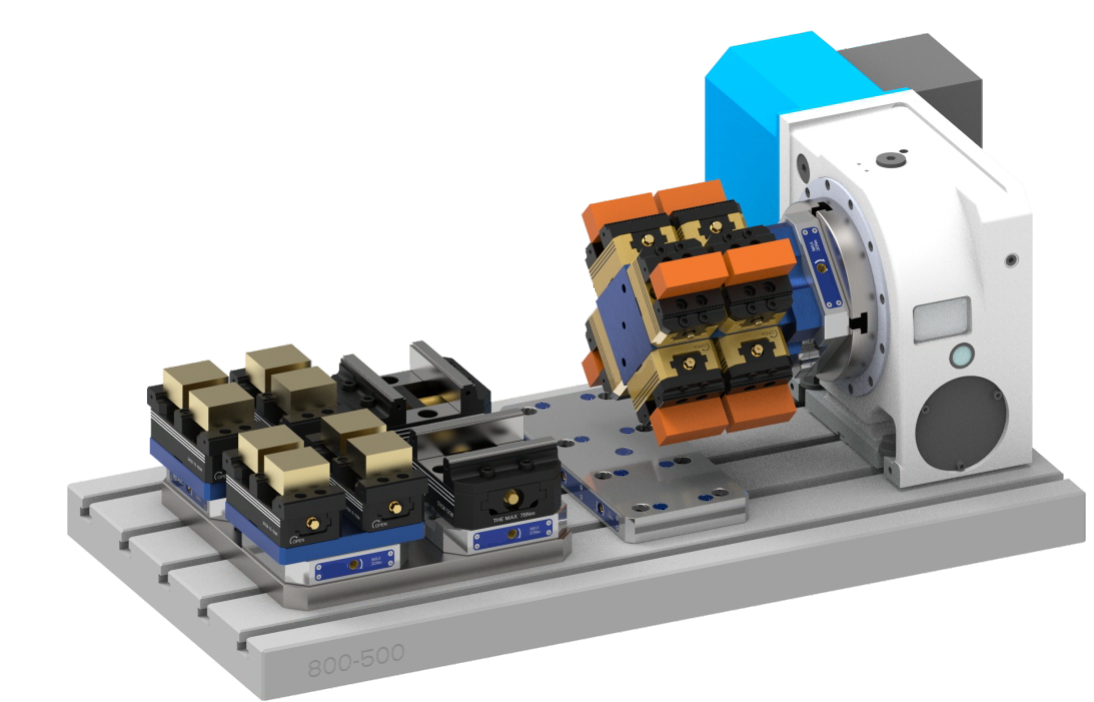

As the interface between the machine tool table and the clamping device, NBD's zero-point quick change system has a variety of transformations. It can be universally used in 3-axis, 5-axis tables and 4th-axis vertical and horizontal machining centers.

4. Optimize your workbench and improve efficiency

4. Optimize your workbench and improve efficiency

Increase the clamping station of the machine tool itself to improve processing capabilities and minimize downtime.

5. Optimization program

This facilitates the tool to reach the workpiece to a greater extent and reduces tool changing time.

6. Optimize the replacement time

Clamping tools, fixtures and workpieces can be changed with high precision within seconds.

Each product and each new process requires a dedicated fixture and adapter tool plate. This is actually one of the biggest reasons affecting the efficiency of machine tools. A large amount of adaptation work makes it difficult for high-precision machine tools to fully exert their capabilities. We should pay attention to the direction of clamping technology, and the efficient combination of quick change + clamp is the top priority.